Unveiling the Cornerstone of New Energy Battery Safety and Performance - Cell Charge-Discharge Testing

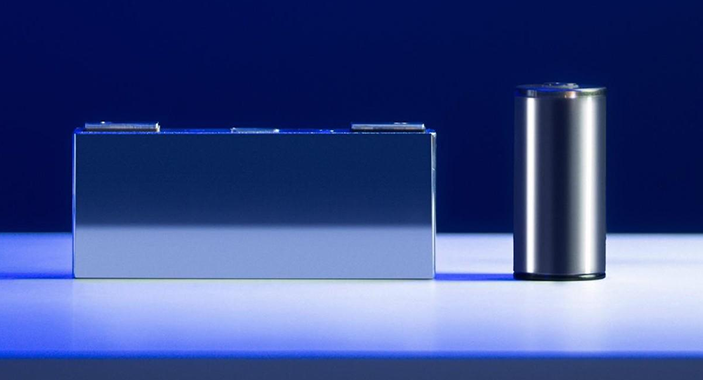

As the core carrier for energy storage and conversion, batteries have deeply penetrated key fields such as consumer electronics, electric vehicles, and large-scale energy storage systems, becoming a core force driving the transformation of the energy structure. Cells, as the smallest functional unit of batteries, their performance, quality, and safety directly determine the overall performance of the entire battery system.

Therefore, conducting a comprehensive performance "check-up" on cells and identifying potential safety hazards in advance are crucial prerequisites for ensuring the stable and efficient operation of cells in various complex application scenarios - and thus the cell charge-discharge testing system has emerged. By accurately simulating various charge-discharge scenarios of cells in practical applications, this system can not only accurately obtain core performance parameters such as capacity, internal resistance, and cycle life but also provide core data support for cell design optimization, quality control, and safety assessment.

From the front-end links of cell R&D and production to the back-end links of application and retirement recycling, the charge-discharge testing system can meet the core needs of different fields through "precision testing + data support":

Accelerate R&D Innovation and Shorten the Technology Iteration Cycle

In the cell R&D stage, the charge-discharge testing system can accurately simulate actual working conditions such as different charge-discharge rates, temperature environments, and cycle times, providing comprehensive and high-precision data support for R&D personnel. By analyzing the test data, R&D teams can quickly screen out the optimal design schemes, optimize material formulas and production processes, effectively shorten the R&D cycle, reduce R&D costs, and help new high-performance cells be put into use faster.

Strictly Control Production Quality and Ensure Product Consistency

During the cell production process, affected by factors such as raw material fluctuations and process complexity, even products from the same production line may have performance deviations. The charge-discharge testing system can conduct full-parameter testing on each cell. Through strict screening and grading, it ensures that the performance of the cells leaving the factory fully meets the standards, significantly improving the overall product quality and stability. At the same time, based on the test data, enterprises can quickly locate the root causes of problems in the production process, adjust process parameters in a timely manner, reduce the defect rate, and improve production efficiency.

Strengthen Safety Assessment and Avoid Application Risks

Safety is the primary prerequisite for cell applications. Whether it is the power supply for electric vehicles during high-speed driving or the long-term charge-discharge of energy storage power stations, once a cell has a safety problem, it may lead to serious consequences. The charge-discharge testing system comprehensively evaluates the safety performance of cells by simulating extreme working conditions such as overcharge, over-discharge, short circuit, and high temperature, and identifies potential hazards in design or manufacturing in advance. Based on the test results, enterprises can make targeted improvements to product design and production processes, enhance the cell safety level from the source, and provide protection for downstream applications.

Facilitate Echelon Utilization and Promote Sustainable Industrial Development

With the expansion of the battery industry scale, the environmental protection treatment and resource recycling of retired batteries have become industry pain points. The charge-discharge testing system can conduct accurate performance evaluation on retired cells to determine their remaining use value: for cells whose performance still meets the standards, they can be guided to scenarios with lower performance requirements such as low-speed electric vehicles and distributed energy storage to realize echelon utilization, extend the cell lifecycle, and reduce resource waste; at the same time, the detailed data provided by the system also provides a scientific basis for the subsequent recycling of cell materials, helping to build a green closed loop of "production - use - recycling".

GEEKTEST - Cell Charge-Discharge Testing System

Product Introduction

The GTC series energy feedback-type cell charge-discharge testing system is a high-precision system specially designed for cell testing. Integrating a power module, a control unit, and a data acquisition module, this system builds a fully functional comprehensive cell measurement and control platform, which can meet the full-lifecycle testing needs of cells throughout R&D, production and manufacturing, testing and certification, echelon utilization, and recycling.

With its outstanding testing precision and adaptability, it is widely used in fields such as power cells, energy storage cells, and large-capacity cells, meeting the diverse testing needs of cell manufacturers, testing institutions, etc., and is crucial for ensuring cell performance and quality.

Product Features

• Ultra-high precision testing of 0.02% F.S. with intelligent current 档位 division in three ranges

• Fast dynamic response of 3ms and high-speed recording of 5ms, suitable for various high-speed dynamic testing applications

• Modular design with independent channel control, flexible system expansion, enabling different powers, and convenient installation and maintenance

• Support for multi-channel parallel connection function, allowing parallel connection of any channels, with channels capable of being paralleled up to 5000A

• Third-party access, supporting voltage/temperature/expansion force/temperature chamber/water chiller, etc., to achieve efficient linkage and multi-equipment coordinated operation

• Multi-layer protection, with multi-layer hardware and software protection mechanisms to achieve comprehensive protection of the equipment system, batteries, and data, ensuring the safety and reliability of batteries during testing

• Support for 24-hour offline operation, with data recoverable after offline operation to protect data integrity

• Pulse characteristics: support for pulse formation and capacity grading, which effectively improves the formation of the SEI film and achieves comprehensive improvement in efficiency, precision, safety, and economy

• Negative pressure testing, optional -6V, four-quadrant topology, expanding the exploration of performance boundaries

• Equipped with HPPC testing capability for evaluating the power performance and dynamic characteristics of lithium batteries

• 20ms working condition, supporting the import of 1 million-line files, accurately capturing the dynamic performance of batteries under actual working conditions

• Support for NEDC, WLTP, CLTC, and EPA working condition testing

Product Parameters

Input Indicators | Rated Grid Voltage/Frequency | Three-phase five-wire system, 380±10% VAC, 50/60 Hz |

Voltage | Voltage Range | 0V~5V/6V |

Voltage Precision | ± 0.02% F.S | |

Current | Current Range | ±0~5000A, intelligent division |

Current Precision | ± 0.02% F.S. (current range) | |

Resolution | Voltage & Current | 24bit |

Time | Current Response Time | 3ms (10%~90% F.S) |

Data Recording | Minimum Recording Time Interval | 5ms |

Power | Power Precision | 0.05%FS |

Resolution | 0.1W | |

Efficiency | Optimal Efficiency of Module Charge-Discharge | ≥91% |

Working Modes | Charge-Discharge Modes | CC, CV, CC-CV, CP, CR, CP-CV, CR-CV, DCR, Ramp, Pulse |

Special Working Modes | Working condition simulation, pulse testing, DCIR testing, HPPC testing | |

Working Conditions | Working Condition Road Spectrum | 20ms |

Number of Working Condition Points | 1 million | |

Pulse | Minimum Pulse Width | 20ms |

Number of Pulses | 32 | |

Ramp | Ramp Modes | Current ramp, power ramp, ramp voltage |

Number of Ramps | 32 | |

Software Functions | Customization | Variable function operation, supporting custom function expressions |

Curve | Customizable graphing, supporting 6 Y-axes, supporting multi-channel curve comparison | |

Data | Supporting custom report data export, supporting automatic data backup | |

System Connection | Support for Access to Third-Party Systems | MES/LIMS, etc. |

Safety Protection | Hardware and Software Protection | Overcurrent/overvoltage/undervoltage/reverse connection/wrong connection/communication abnormality protection/voltage line missing connection, etc. |

Auxiliary Channels | Auxiliary Acquisition Module | Optional temperature and voltage |

Operating Environment | Operating Temperature and Humidity | 10℃~40℃, 10-90%RH (no condensation) |

Cooling Method | Air cooling | |

Noise Level | ≤75dB | |

Protection Level | IP20 |

With the continuous advancement of battery technology and the continuous expansion of application fields, higher requirements have been put forward for the performance and functions of cell charge-discharge testing systems. As a professional provider of testing systems and automated production lines in the new energy industry, Shenjice will closely follow the development trend of new energy technology, actively respond to the national "dual carbon" policy call, continue to increase R&D investment, constantly upgrade product performance and service systems, and inject more strength into promoting the high-quality and sustainable development of the new energy industry.

Add WeChat

Add WeChat